Total Installed Cost (TIC) Estimation

⦁ QPlant estimates the total installed construction cost for process facilities and pipelines, providing a comprehensive view that includes materials, labor, equipment, and overhead. It produces Class 4 estimates with minimal effort—often just a button press—making it ideal for early conceptual stages when project costs are least understood. Class 3 estimates can be produced with user provided equipment quotes.

Integration with Process Simulations

⦁ QPlant can integrate with process simulation software to extract data directly from process models. This allows it to analyze process schemas and generate cost estimates based on design parameters, reducing manual input and errors. It can translate PFD (Process Flow Diagram) data into construction cases, using heuristics, auto-design, and piping layout rules to determine equipment and piping quantities.

Automated Material Take-Off (MTO)

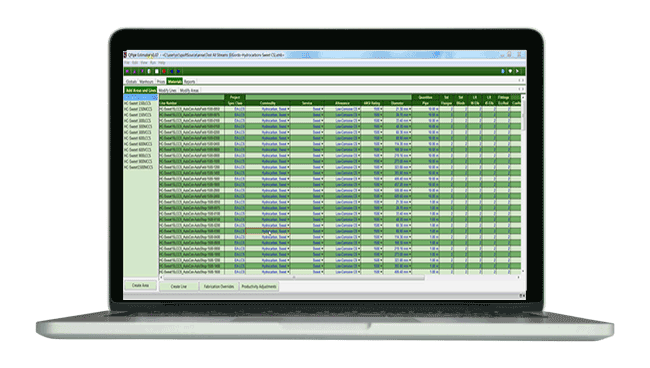

⦁ The software automates the material take-off process by extracting data from smart P&ID programs like AutoCAD and SmartPlant (3D and P&IDs). This capability significantly reduces the time and effort required for manual MTOs, delivering higher accuracy and manhour savings compared to traditional methods. It organizes estimates in multiple configurations, allowing easy manipulation and re-allocation of MTO data.

Real-Time Adjustments and Flexibility

⦁ The software supports real-time adjustments to engineering changes, enabling rapid recalculation of detailed project costs driven by process and design iterations. It offers location- and spec-driven calculations, allowing users to select country/region settings and adjust for geographic variations in costs.

Ease of Use and Minimal Expertise Required

⦁ Designed as a standalone tool, QPlant empowers both cost estimators and facility/pipeline designers with an intuitive interface. Expert systems set intelligent defaults, requiring very little construction or cost estimating expertise to generate reasonable estimates. Deeper details for specific project conditions are easy to access and adjust.

Data Integration and Connectivity

⦁ QPlant can connect to a wide array of data sources, including Microsoft Excel, XML, SQL databases, ISOGEN PCF files, and process simulators. It supports simple MS Excel imports and exports, real-time currency conversions, and custom data mappings for maximum flexibility. This connectivity ensures seamless integration into existing workflows and business processes.

Compliance and Standards

⦁ The software is compliant with industry standards like ASME B31.3 and B31.1, ensuring rule-based, accurate cost estimations that align with regulatory and engineering requirements for industrial piping and facilities.

Detailed Reporting and Granularity

⦁ QPlant offers detailed reporting capabilities, providing detailed, granular insights into cost projections. This feature supports project teams in making informed decisions by offering transparent, structured datasets for analysis.

Early-Stage Economic Evaluation

⦁ By delivering accurate TIC projections early in the conceptual design phase, QPlant accelerates economic evaluation intelligence. It helps project teams consider CAPEX (capital expenditure) estimates in design decisions, reducing capital costs through informed, data-driven insights.

Scalability and Customization

⦁ QPlant is designed to handle projects of varying sizes and complexities, from small facilities to large-scale industrial plants. It supports customization of data based on varied process design.

Seamless Data Flow and Reduced Manual Input

⦁ QPlant’s integration with process simulators, smart P&ID programs (e.g., AutoCAD, SmartPlant 3D and P&IDs), and other tools eliminates the need for manual data entry.

Enhanced Accuracy in Early-Stage Estimates

⦁ Integration with process simulations and CAD systems allows QPlant to generate highly accurate total installed cost (TIC) estimates early in the conceptual design stage.

Improved Workflow Efficiency

⦁ QPlant’s ability to connect with Microsoft Excel, XML, SQL databases, ISOGEN PCF files, and other data formats ensures seamless integration into existing workflows. Users can import and export case data easily, manipulate estimates in multiple configurations, streamlining collaboration across teams and departments.

Flexibility for Custom Data Needs

⦁ Integration with diverse data sources and customizable mappings allows QPlant to handle complex, industry-specific data challenges, such as model dumps and PCF files.

Better Decision-Making with Real-Time Insights

⦁ QPlant’s integration capabilities enable real-time adjustments, empowering project teams to analyze CAPEX (capital expenditure) estimates in design decisions, reducing capital costs and supporting more informed investment choices.

Scalability Across Projects and Industries

⦁ The integration features make QPlant scalable for projects of varying sizes and complexities, from small facilities to large industrial plants across a wide range of industries by connecting with industry-standard tools, consistently and reliably across diverse applications.

Cost Reduction and Risk Mitigation

⦁ By minimizing errors, speeding up estimating cycles, and providing reliable early-stage projections, QPlant’s integrations reduce financial risks associated with over- or under-estimating. This is particularly valuable for competitive bidding, budget planning, and securing investor confidence in capital projects.

User-Friendly Interface with Expert Systems

⦁ Integration with advanced tools enhances QPlant’s user-friendly design, where expert systems set intelligent defaults based on integrated data (e.g., geographic locations, vendor specifics). This allows users with minimal estimating expertise to generate accurate results quickly, broadening accessibility across teams.

Enhanced Reporting and Collaboration

⦁ QPlant’s integration enables detailed, granular reporting by pulling data from multiple sources, providing unmatched transparency and granularity for stakeholders. This facilitates collaboration between engineers, estimators, and financial teams, ensuring alignment on project costs and outcomes.

QPlant Reporting Capabilities

-

Granularity and Detail

Granularity and Detail

-

Real-Time Reporting and Updates

Real-Time Reporting and Updates

-

Customizable and Flexible Report Formats

Customizable and Flexible Report Formats

-

Integration with Data Sources for Comprehensive Insights

Integration with Data Sources for Comprehensive Insights

-

Location- and Spec-Driven Calculations

Location- and Spec-Driven Calculations

-

Easy Export and Sharing via MS Excel

Easy Export and Sharing via MS Excel

-

Visual and Interactive Reporting

Visual and Interactive Reporting

-

Support for Early-Stage Economic Evaluations

Support for Early-Stage Economic Evaluations

-

Audit Trails and Traceability

Audit Trails and Traceability

-

Scalability for Large-Scale Projects

Scalability for Large-Scale Projects